Sodium Dichloroisocyanurate (SDIC) is a chlorinated disinfectant widely used in swimming pools, drinking water, industrial water treatment and hygiene fields. Its popularity lies in its high effective chlorine content, good stability and ease of operation. Unlike liquid chlorine, SDIC is solid and available in various dosage forms such as granules, tablets and powders. Each dosage form has unique properties and is suitable for different applications.

SDIC contains cyanuric acid, which can stabilize chlorine and reduce the rate of chlorine loss caused by sunlight exposure. This makes SDIC more resistant to ultraviolet degradation than liquid chlorine (sodium hypochlorite). However, understanding its formula, dissolution characteristics and packaging requirements is crucial for maintaining its effectiveness during storage and transportation.

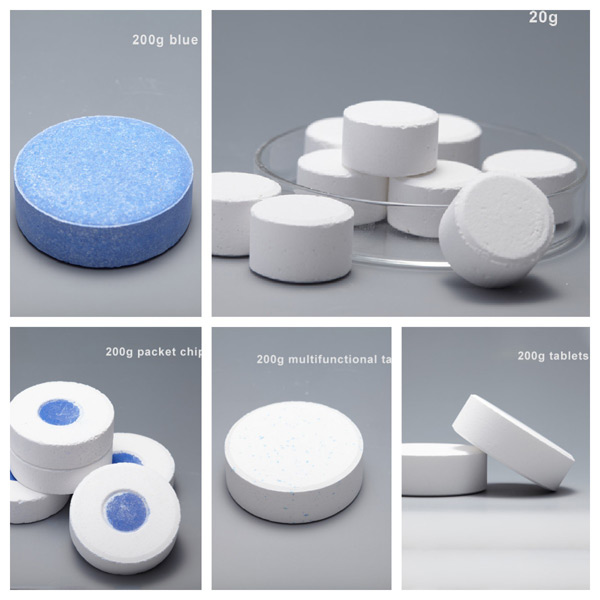

Sodium Dichloroisocyanurate Preparations and Their Characteristics

Granular sodium dichloroisocyanurate (SDIC) is widely used in industrial water treatment, municipal water purification and swimming pool shock treatment. The particles can rapidly release hypochlorous acid after dissolving in water.

Main features

Quick dissolution: It is an ideal choice for rapid disinfection

Application fields: Large-scale water treatment, swimming pools and emergency disinfection

Effective chlorine content: Usually 56-60%

Stability: Sensitive to humidity; It must be kept dry

It dissolves quickly and is suitable for occasions where the chlorine effect needs to be exerted immediately. ; For example, swimming pool shock

In addition to regular tablets, SDIC is also commonly produced as effervescent tablets and flavored tablets. They are frequently used for routine pool maintenance, home disinfection, water dispensers and portable water treatment equipment, and wilderness first aid.

Key features: Dissolves quickly and leaves no residue.

Applications: Home disinfection, portable water purifiers, wilderness first aid.

Available chlorine content: 54%. Depending on the pressing process and formulation, effervescent or flavored tablets may have a lower available chlorine content.

Stability: Due to the presence of cyanuric acid, it is resistant to UV radiation and high temperatures. Easy to store and carry.

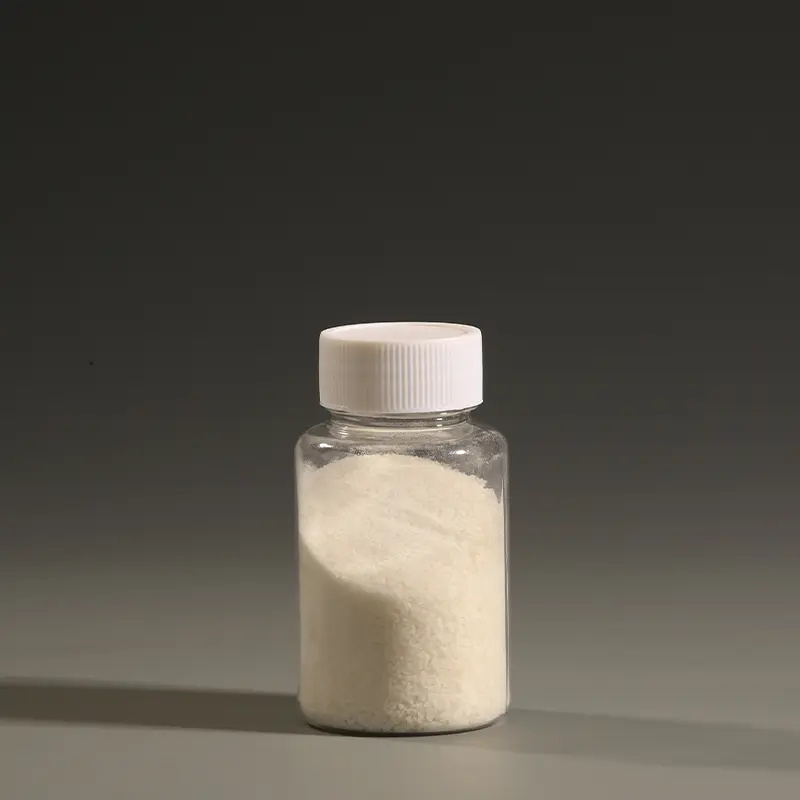

Sodium Dichloroisocyanurate Powder

SDIC powder has high purity and dissolves rapidly, making it suitable for industrial or laboratory applications. Powdered products can be precisely measured and are often mixed with other chemicals for water treatment.

Main features

Rapid dissolution: Chlorine takes effect immediately

Application fields: Industrial water, laboratory water

Effective chlorine content: 60%

Stability: It is hygroscopic, so moisture-proof packaging is of vital importance.

SDIC powder should be handled with care to avoid inhaling dust.

Factors Affecting the Stability of NaDCC

· Ultraviolet rays and light

Like all chlorine disinfectants, sunlight causes decomposition of SDIC, however, cyanuric acid structure can protect SDIC and making it more stable than liquid chlorine under sunlight.

· Humidity

It may cause the tablets to clump or dissolve.

Suggestion: Store SDIC in sealed and moisture-proof packaging, such as HDPE drums, aluminum foil bags or multi-layer composite bags with desiccants.

· Temperature

Below 40°C: Can be stored stably for a long time

Proper storage in a cool and well-ventilated warehouse is of vital importance, especially for long-distance exports.

|

Factor |

Effect on Stability |

Recommended Protection |

| Moisture | Causes hydrolysis and chlorine loss | Airtight packaging with desiccants |

| UV Light | Minimal effect (cyanuric acid provides stability) | Opaque containers or foil bags |

| Heat | High temperature accelerates decomposition | Store below 40°C |

| Impurities | Catalyze chlorine loss | Use high-purity raw materials |

Packaging Suggestions for Different SDIC Forms

Sodium Dichloroisocyanurate Granules

Packaging: High-density polyethylene drum, moisture-proof aluminum foil bag

Required protective measures: Prevent moisture absorption and mechanical damage

Recommended application fields: industrial water, municipal water, swimming pools.

Sodium Dichloroisocyanurate Tablets

Packaging: Individual packaging, then placed in aluminum foil bags or cartons; Bulk tablets are packed in high-density polyethylene drums with linings.

Required protective measures: Avoid fragmentation or damage; Prevent moisture

Recommended markets: swimming pools, drinking water, disaster relief

Sodium Dichloroisocyanurate Powder

Packaging: Sealed high-density polyethylene drums or composite laminated bags

Required protective measures: Prevent dust and moisture

Recommended markets: Industrial water treatment, laboratories, etc

|

Form |

Recommended Packaging |

Key Functions |

Export Market Examples |

| Granules | HDPE drums or foil-lined bags | Moisture-proof, impact-resistant | Latin America, Middle East |

| Tablets | Individual wrapping + foil bags + cartons | Prevent moisture and breakage | EU, North America, Southeast Asia |

| Powder | Composite bags with inner liners | Anti-dust and moisture-proof | Africa, Industrial markets |

Tip: For humid climates (like Indonesia, Thailand, Brazil), include a desiccant sachet in each container to ensure chlorine stability during shipping.

Best Practices for NaDCC Storage and Export

Cool and dry environment: Avoid high temperatures and humidity.

Isolate from incompatible chemicals: Avoid contact with acids, ammonia, organic substances and reducing agents.

Moisture-proof packaging: high-density polyethylene drums, aluminum foil bags, and composite bags containing desiccants

Regulatory compliance: Adhere to the transport standards of United Nations Convention No. 2465, the labelling requirements of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), and local import regulations.

Exporters should customize packaging based on climate and market conditions: In humid regions (Southeast Asia), additional moisture-proof protection may be required; Standard packaging may be required in arid regions (Latin America, Africa).

Selecting the appropriate SDIC formula and packaging is crucial for maintaining its stability, chlorine content and performance. By choosing the appropriate SDIC form and packaging, manufacturers and exporters can ensure the effectiveness of their products, a longer shelf life and the satisfaction of global customers.

Post time: Nov-12-2025