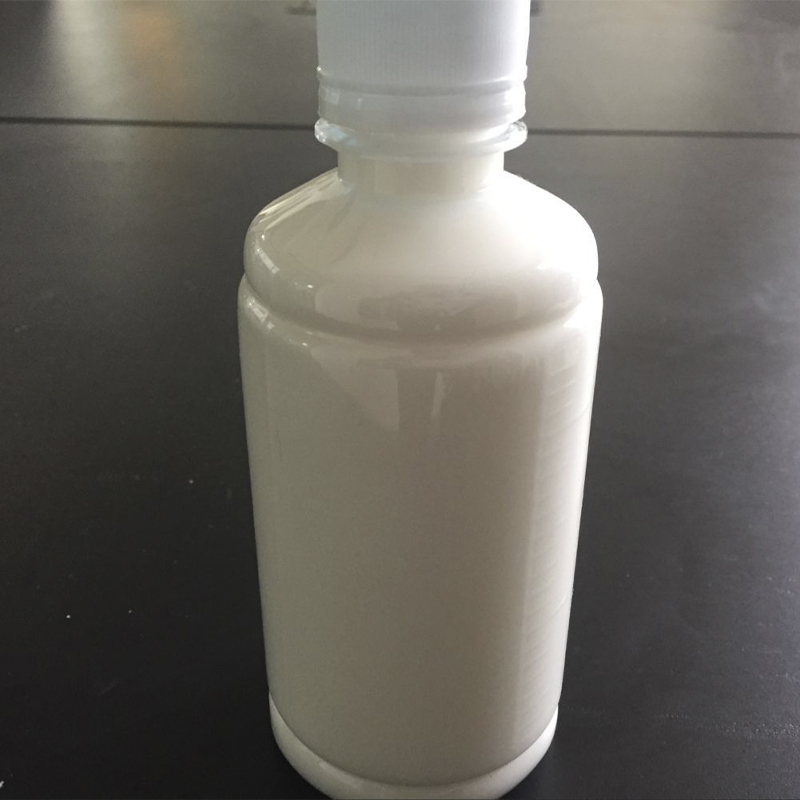

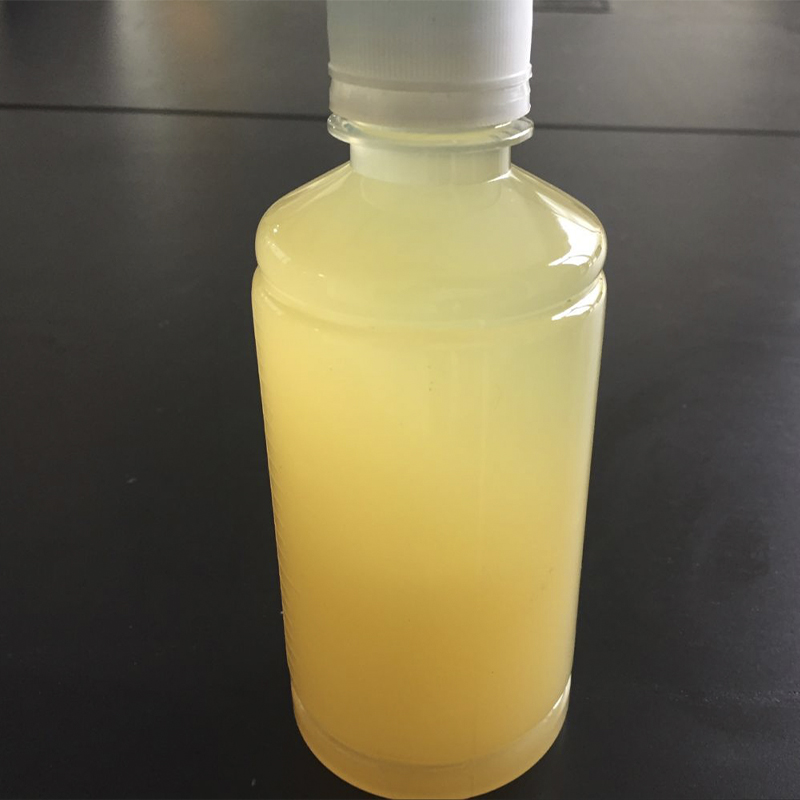

The third generation defoamer is a silicone defoamer based on polydimethylsiloxane (PDMS, dimethyl silicone oil). At present, the research and application of this generation of defoamers are basically concentrated in China. PDMS is composed of silicon oxygen chain and other organic groups, and can not be tightly arranged on the foam liquid film, so that the bubbles will burst. Low viscosity PDMS has good defoaming property and high viscosity PDMS has good defoaming property.

Advantages of silicone defoamer

It has good chemical inertia and is difficult to react with other substances. It can be used in acid, alkali and salt solutions.

Good physiological inertia, can be used in food and pharmaceutical industries, and has no pollution to the environment.

It has good thermal stability and low volatility, and can be used in a wide temperature range.

The viscosity is low and spreads rapidly at the gas-liquid interface.

Surface tension as low as 1.5-20 Mn / M (76 Mn / m for water).

It is not easy to be solubilized by surfactant in foaming system.

Low dosage, low viscosity and low flammability.

Disadvantages of silicone defoamer

1. It is difficult to disperse in water system.

2. Because it is soluble in oil, the defoaming effect in the oil system is reduced.

3. Poor high temperature resistance.

4. Poor resistance to strong alkalinity.

High cost: PDMS is a water in oil (O/W) emulsion made of silicone grease, emulsifier, thickener, etc., which is emulsified by water. The surface tension decreases rapidly and has strong anti foaming and anti foaming effects. It is roughly divided into three formulations: silicone oil, silicone oil + modified polyether and polyether modified silicone oil.

It is characterized by: Low surface tension, high surface activity and strong defoaming power.

Less dosage: It can inhibit and break bubbles for most bubble media. It has good thermal stability and can be used in a wide temperature range. It is shared with polyether and has synergistic effect. It is widely used for defoaming in detergent, papermaking, pulp, sugar making, electroplating, chemical fertilizer, additives, wastewater treatment and other production processes. In the petroleum industry, it is widely used for desulfurization of natural gas to accelerate oil-gas separation; It is also used to control or suppress bubbles in devices such as ethylene glycol drying, aromatic hydrocarbon extraction, asphalt processing and lubricating oil dewaxing. In textile industry, it is used for defoaming in dyeing, scouring, sizing and other processes; It is used in the process of chemical emulsion and defoaming in industry; It is used for defoaming in various concentration, fermentation and distillation processes in the food industry.

Post time: May-05-2022