In today’s fast-paced industrial landscape, foam formation can present a significant challenge—disrupting production, damaging equipment, and compromising product quality. To address this, Antifoam Agents, also known as defoamers, have become indispensable across various industries such as pharmaceuticals, food and beverage, water treatment, and chemical manufacturing.

What Is an Antifoam Agent?

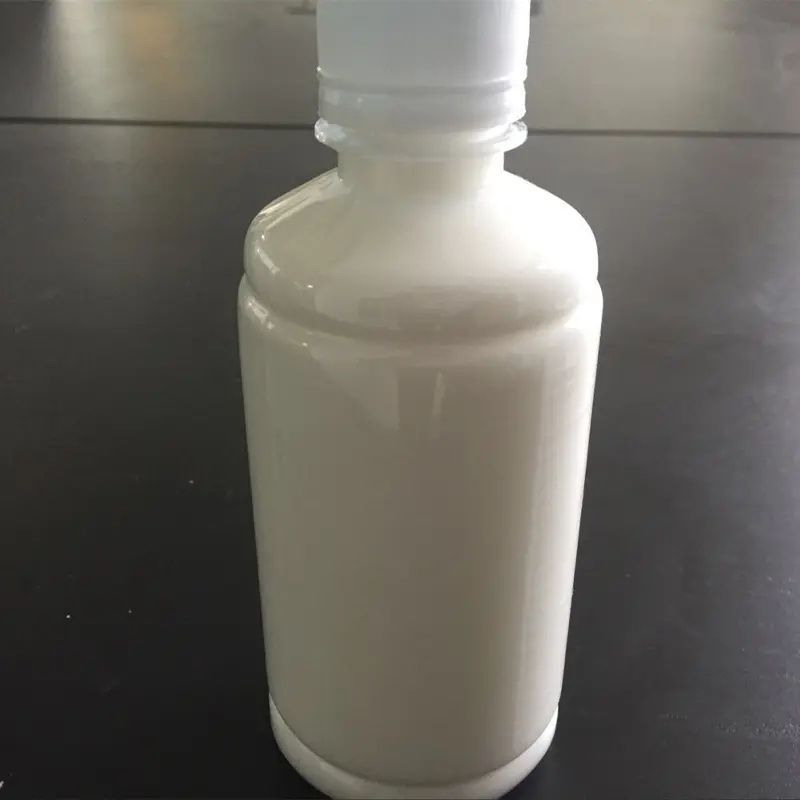

An ntifoam agent is a chemical additive specifically designed to prevent and eliminate foam generation during industrial processes. Foam forms when air or gas is introduced into liquid systems, often due to agitation or chemical reactions. While seemingly harmless, foam can reduce operational efficiency, cause overflow, impair heat transfer, and interfere with accurate liquid measurements.

Antifoam agents work in two ways:

1. Breaking down existing foam by destabilizing the bubbles.

2. Preventing new foam from forming by spreading across the surface and reducing surface tension.

Defoamer Applications Across Key Industries

1. Pharmaceutical Industry

In pharmaceutical manufacturing, maintaining strict process control is essential. During the production of vaccines, antibiotics, and other formulations, foam can hinder mixing and fermentation processes. Antifoam agents are used to ensure smooth operation, preserve sterile conditions, and enhance final product quality.

2. Food and Beverage Industry

Foam is commonly encountered in food processing—especially in brewing, dairy production, and sauces manufacturing. Using food-grade antifoam agents helps prevent overflow and ensures consistency in texture, taste, and appearance. This leads to higher productivity, improved hygiene, and reduced product loss.

3. Chemical Manufacturing

Chemical production often involves reactions that release gases, resulting in foam. Excessive foam can interfere with chemical reactions and equipment efficiency. Antifoam agents help maintain process stability, reduce downtime, and increase yield by controlling foam-related disruptions.

4. Water Treatment and Industrial Cleaning

Foam can also pose problems in water treatment systems, especially in aeration tanks, cooling towers, or during surfactant-heavy cleaning processes. Specialized antifoam formulations ensure smooth operation and help facilities meet environmental discharge regulations.

Growing Market and Sustainable Innovation

The global demand for antifoam agents is growing steadily, driven by rising industrial automation and the need for process optimization. As sustainability becomes a top priority, manufacturers are developing biodegradable and non-toxic antifoam formulations to meet regulatory standards and reduce environmental impact.

Antifoam agents play a critical role in enhancing efficiency, protecting equipment, and maintaining product integrity across a wide range of industries. As manufacturing technologies evolve and environmental standards tighten, the importance of high-performance, eco-friendly antifoam solutions will continue to grow.

For businesses aiming to optimize their production lines and meet modern compliance requirements, incorporating the right antifoam agent is no longer optional—it’s essential.

Post time: Dec-20-2023