Water has always been one of the world's most precious resources. With increasing industrial production and accelerating urbanization, water security, sustainability, and treatment efficiency are becoming critical global issues. In municipal water facilities and industrial wastewater treatment plants, stricter environmental regulations, rising operating costs, and growing public awareness are reshaping how water is treated, recycled, and reused.

By 2026, the global industrial and municipal water treatment industry will continue to evolve towards higher efficiency, greater sustainability, enhanced safety, and smarter technology integration. For manufacturers, distributors, and project operators involved in water treatment chemicals, disinfectants, flocculants, and integrated treatment solutions, understanding these future trends is crucial for strategic planning and market positioning.

This article will explore key trends in industrial and municipal water treatment to watch for in 2026, highlighting market direction, technological innovations, regulatory changes, and their practical implications for manufacturers, distributors, engineering firms, and end-users.

More than 2 billion people worldwide live in water-scarce regions, and this number is constantly increasing. Industrial production, agriculture, and urban expansion all require large quantities of clean and safe water. As freshwater resources become increasingly strained, wastewater recycling and treatment are no longer optional but a strategic necessity.

Stricter Environmental Regulations

Governments worldwide are tightening emission limits for the following pollutants:

- Suspended solids

- Heavy metals

- Phosphorus and nitrogen

- Organic pollutants

- Microplastics

- Pathogens

This directly drives the development of chemical treatment solutions, filtration systems, and monitoring technologies.

Industrial and Infrastructure Modernization

For example, in the following industries:

- Petrochemicals

- Mining

- Pulp and paper

- Food processing

- Textiles

- Electronics manufacturing

All these organizations are upgrading their water supply systems to improve efficiency, reduce risks, and meet ESG goals.

Meanwhile, municipal water treatment plants are modernizing aging infrastructure to ensure a safe drinking water supply.

Key Trend 1: Strong Demand for Coagulation and Flocculation Chemicals

Coagulation and flocculation remain central to water clarification processes. The industrial flocculant and coagulant market will continue to expand in 2026, particularly in Asia, Latin America, and the Middle East.

Popular chemicals driving this growth include:

- Polyaluminum chloride (PAC)

- Polyacrylamide (PAM)

- Polyamines (PA)

- Poly(diallyldimethylammonium chloride) PolyDADMAC

- Ferric chloride

These chemicals help remove:

- Suspended solids

- Oils

- Sludge

- Heavy metals

- Organic matter

Why is demand growing?

- Higher emission standards

- More wastewater recycling systems

- Industrial expansion

- Cost-effective performance

- Reduced sludge volume compared to traditional alum.

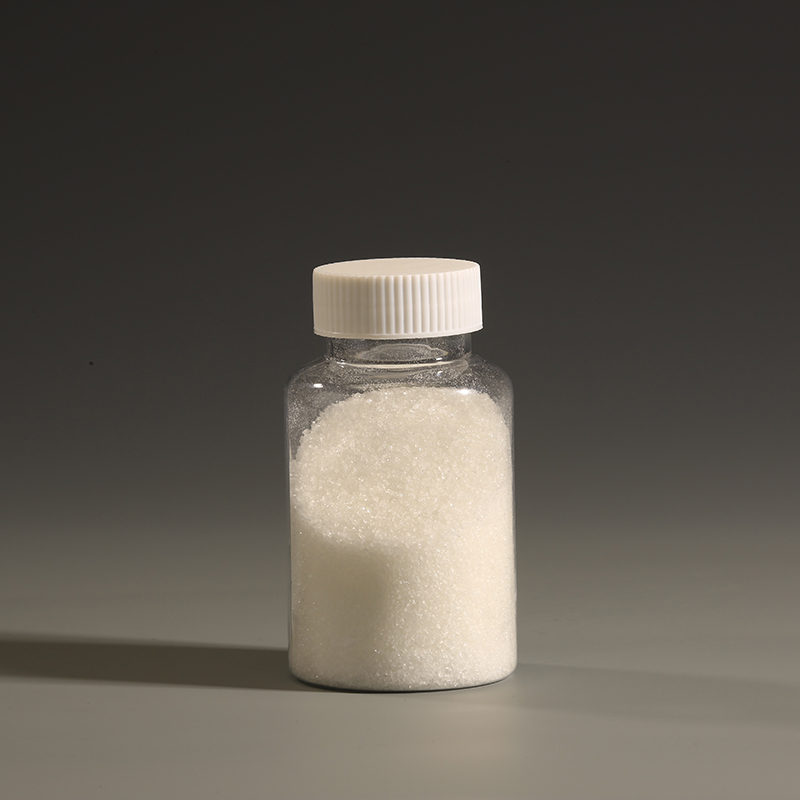

PAC and PAM maintain market leadership

PAC (polyaluminum chloride) continues to dominate in clarification and sedimentation processes for drinking water and wastewater treatment due to:

- High coagulation efficiency

- Wide pH adaptability

- Rapid settling performance

- Competitive cost

Polyacrylamide, particularly anionic and cationic polyacrylamide, plays a significant role in sludge dewatering, solid-liquid separation, and flotation processes.

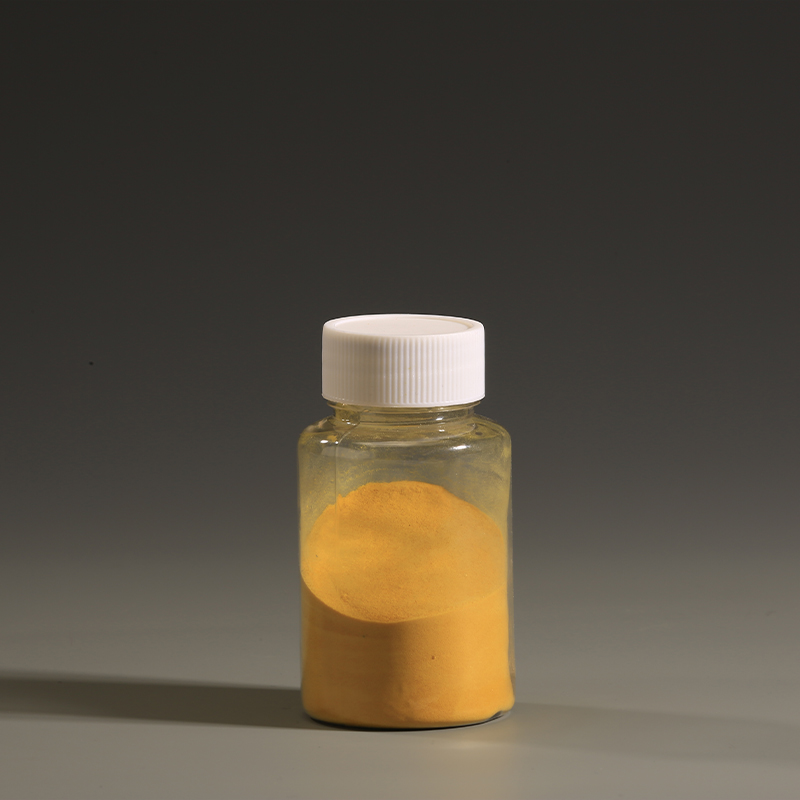

Key Trend 2: Advanced Oxidation and Disinfection Solutions

Pathogens and emerging contaminants, such as pharmaceuticals and organic chemicals, require more advanced treatment technologies.

Key growth areas include:

- Chlorine-based disinfectants (e.g., sodium dichloroisocyanurate, trichloroisocyanuric acid, calcium hypochlorite, etc.)

- Peracetic acid

- Ozone treatment

- Ultraviolet (UV) disinfection

- Advanced oxidation processes (AOPs)

Municipal water systems, in particular, rely on stable and reliable disinfectants to ensure safe drinking water.

Why this trend is important:

- Public health protection

- Reduced disease transmission

- Compliance with WHO guidelines

- Safe distribution in pipeline networks

For industrial applications, microbial control in cooling towers, process water, and wastewater remains critical to avoid corrosion, scaling, and safety risks.

Key Trend 3: Strong Growth in Water Recycling and Reuse

By 2026, zero liquid discharge (ZLD) systems and water reuse plants will gain momentum.

Industries adopting water reuse include:

- Power generation

- Mining

- Semiconductors

- Refining

- Food and beverage

- Pharmaceuticals

Expansion drivers:

- Rising water costs

- Environmental responsibility

- Industrial sustainability goals

- Statutory emission limits

Coagulation, flocculation, membrane filtration, and disinfection chemicals all play a crucial role in these systems.

Key Trend 4: Environmental, Social, and Governance (ESG), Sustainability, and Green Chemistry

Environmental, social, and governance (ESG) standards are influencing purchasing and investment decisions globally.

Companies increasingly require:

- Low-toxicity chemicals

- Biodegradable solutions

- Reduced carbon footprint

- Safer packaging

- Traceable supply chains

By 2026, manufacturers supplying reliable, certified water treatment chemicals will have a significant competitive advantage.

Key Trend 5: Focusing on Drinking Water Safety and Public Health

Clean drinking water remains one of the most important global priorities.

Municipal wastewater treatment plants primarily focus on:

- Pathogen control

- Reducing turbidity

- Removing heavy metals

- Improving taste and odor

- Preventing pipe corrosion

Demand for coagulants, disinfectants, and anti-corrosion chemicals is expected to continue to grow.

Industrial Applications will Expand in 2026

Key industries relying on water treatment include:

- Oil and gas

- Power generation

- Metallurgy

- Chemical processing

- Pulp and paper

- Leather

- Textile manufacturing

- Electronics

- Food industry

- Pharmaceuticals, etc.

Each industry requires specific chemical formulations, compliance documentation, and technical support, creating significant opportunities for specialized suppliers.

The Role of Reliable Chemical Suppliers in 2026

As systems become increasingly complex, customers need more than just products. They need partners who can provide the following services:

- Stable, high-quality supply

- Technical guidance

- Regulatory support

- Customized solutions

- Laboratory testing capabilities

- Competitive pricing

- Long-term partnerships

Coagulation, flocculation, disinfection, and advanced treatment technologies will remain core pillars of the industry. Manufacturers with strong production capabilities, export experience, and international certifications will have a greater advantage in succeeding in this growing market. Companies that can combine high-quality chemicals, technical expertise, and reliable logistics support will become industry leaders in the coming years.

Water treatment is not merely an industry trend; it is a crucial foundation for environmental protection, industrial development, and public health. Looking ahead to 2026, the global demand for reliable, efficient, and sustainable water treatment solutions will continue to grow.

Companies that understand market trends and adopt advanced technologies will be best positioned to seize opportunities in the industrial and municipal sectors.

Post time: Jan-13-2026