In the world of chemical manufacturing, the efficient and smooth operation of processes is crucial. One key factor that can impede productivity and affect product quality is foam formation. To combat this challenge, industries heavily rely on Defoamers, also known as antifoam agents. In this article, we delve into the science behind defoamers, their essential role in chemical manufacture, and how they enable smoother and more efficient processes.

What is a Defoamer?

defoamer is a chemical additive designed to suppress and control foam formation during various industrial processes, particularly in chemical manufacturing. Foam, a collection of gas bubbles trapped in a liquid or solid, may arise due to the introduction of air, agitation, or chemical reactions. This undesired foam formation can lead to several issues, such as reduced product yield, increased processing time, and potential equipment damage.

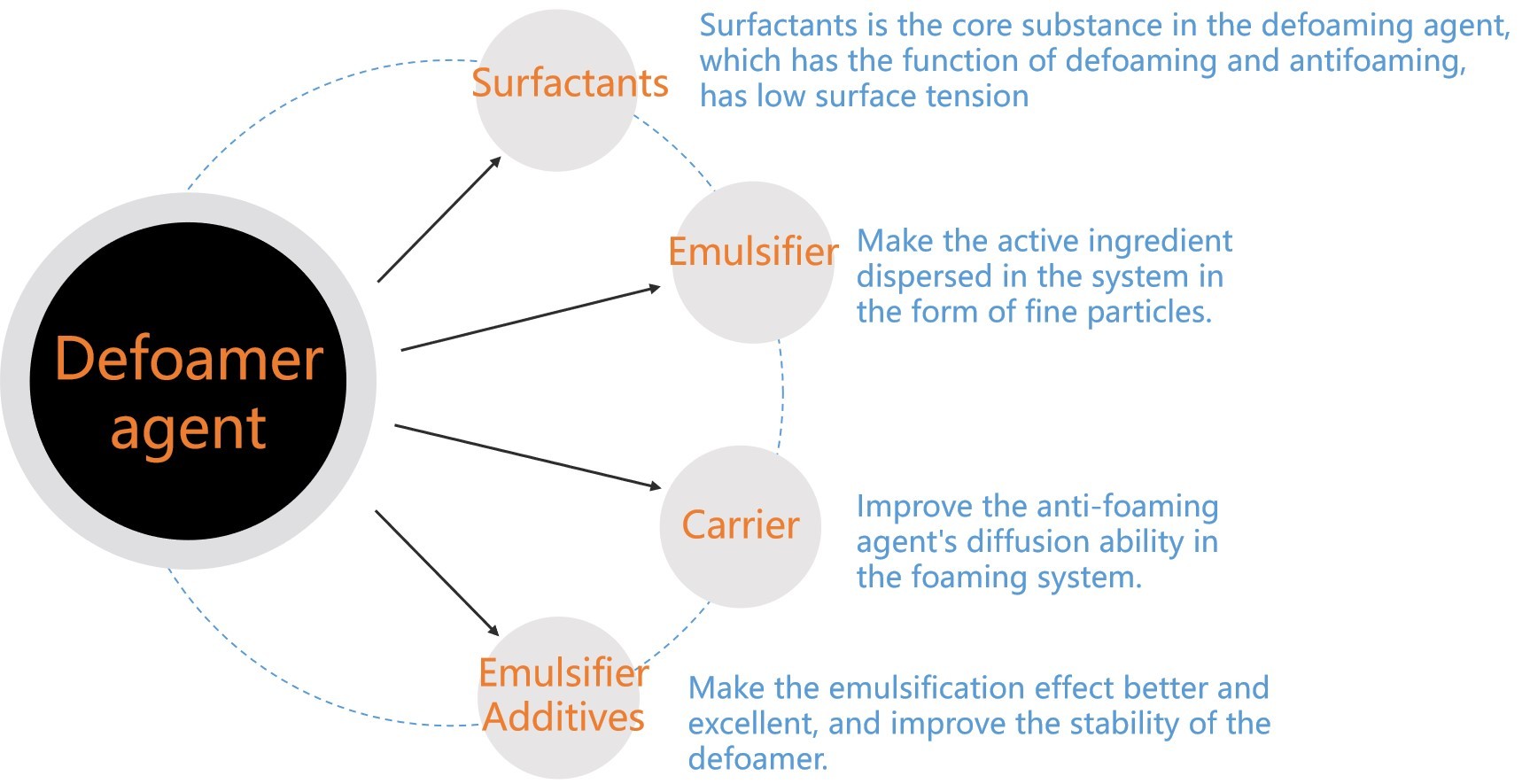

Key Components and Working Principle of Defoamers:

Defoamers are composed of several active components, with silicone-based compounds being the most common. These compounds possess low surface tension, allowing them to spread rapidly across the foam’s surface. Upon contact, defoamers rupture the foam bubbles, leading to the release of entrapped gas. Additionally, defoamers may contain hydrophobic particles or oils that help destabilize the foam structure, ensuring a more effective foam breakdown.

The Application Process:

Defoamers are typically added directly to the foaming system, either manually or through automated injection systems. Due to their low concentration requirements, a small amount of defoamer is usually sufficient to achieve the desired results. The defoamer then disperses throughout the foam and breaks down the bubbles, resulting in a reduced foam volume and improved process efficiency.

Roles of Antifoam Agents in Chemical Manufacture:

Enhanced Process Efficiency:

Foam formation can lead to inefficiencies in chemical manufacturing processes, causing irregular heat and mass transfer. Defoamers help eliminate these issues, enabling consistent temperature distribution and efficient mass transfer throughout the system. This leads to improved reaction rates and higher overall productivity.

Protecting Equipment:

Accumulation of foam in industrial equipment can cause mechanical issues and corrosion. By controlling foam formation, defoamers help protect pumps, reactors, and other critical equipment, thereby extending their operational life and reducing maintenance costs.

Increased Product Yield:

Foam traps valuable components and particles, reducing product yield and purity. Defoamers prevent this loss, resulting in higher product yields and improved product quality.

Safer Working Environment:

Excessive foam can create hazardous conditions for workers, limiting visibility and causing potential slip hazards. Defoamers mitigate these risks by reducing foam and ensuring a safer working environment.

Defoamers in Specific Chemical Manufacturing Processes:

Pharmaceutical Industry:

In pharmaceutical manufacturing, precise control over reactions and product purity is vital. Defoamers play a crucial role in ensuring consistent product quality and high yields during processes like fermentation, where foam can inhibit efficient nutrient exchange.

Food and Beverage Production:

In the food and beverage industry, defoamers prevent excessive foam formation during processes such as fermentation, beer brewing, and soft drink manufacturing. This ensures consistent product texture and taste.

Water Treatment:

In wastewater treatment facilities, defoamers aid in the separation of sludge and effluent, allowing for more efficient water purification and reducing operational costs.

In conclusion, defoamers are indispensable agents in the realm of Chemical Manufacturing. By suppressing foam formation, these additives enhance process efficiency, protect equipment, increase product yields, and create a safer working environment. Their widespread use across various industries highlights the importance of understanding their working principles and optimal application for optimal results. As technology and chemical innovations continue to progress, the role of defoamers in ensuring smoother and more efficient chemical processes is likely to grow even more critical.

Post time: Jul-26-2023