What is PDADMAC?

Polydiallyldimethylammonium chloride (PDADMAC) is a water-soluble cationic polymer recognized for its excellent flocculation, coagulation, and clarification properties. Chemically, PDADMAC is a high-molecular-weight polymer with a high positive charge density, enabling it to strongly interact with negatively charged particles in water.

Key characteristics of PDADMAC include:

- High cationic charge density: Effectively neutralizes negatively charged suspended solids and colloids.

- Water solubility: Can be used in municipal and industrial wastewater treatment without forming insoluble residues.

- Thermal and chemical stability: Effective over a wide pH range and under various water chemistry conditions.

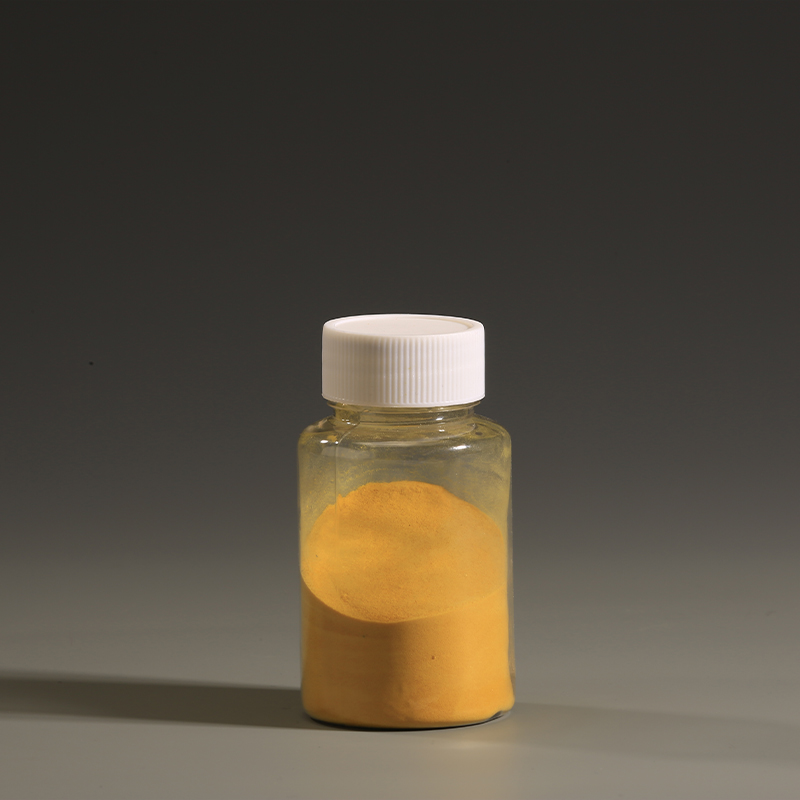

PDADMAC is available in various forms, including liquid (emulsion or solution) and dry powder, offering flexible dosing and easy storage. Its versatility makes it suitable for a wide range of water treatment applications, particularly for turbidity removal and color reduction.

How PDADMAC Removes Turbidity

The primary mechanism by which PDADMAC removes turbidity is charge neutralization. Most suspended particles in water, such as clay, silt, or organic colloids, carry a negative surface charge. These charges create repulsive forces between the particles, keeping them dispersed and preventing sedimentation.

When PDADMAC is added:

- The positively charged polymer chains adsorb onto the negatively charged particles.

- This neutralizes the surface charge, reducing electrostatic repulsion.

- The particles aggregate through bridging to form larger flocs, which are easier to settle or filter out.

This process effectively reduces turbidity, resulting in clearer water suitable for downstream processes such as filtration, disinfection, or reuse. The efficiency of PDADMAC depends on parameters such as molecular weight, charge density, dosage, and water quality characteristics, so precise dosing is crucial for optimal performance.

How does PDADMAC Achieve Color Removal?

The color of water typically originates from dissolved organic matter (DOM), dyes, and industrial wastewater. Turbidity is caused by suspended particles, while color is a property of both dissolved and colloidal substances.

PDADMAC reduces color through the following mechanisms:

- Adsorption: Positively charged PDADMAC molecules attract negatively charged colored molecules, forming flocs that can be removed by sedimentation or filtration.

- Bridging and Aggregation: The polymer chains can link multiple colored molecules, enhancing their removal efficiency.

- Synergistic effect with other coagulants: PDADMAC can be used in combination with alum, ferric chloride, or polyaluminum chloride (PAC) to improve decolorization efficiency, especially in high-chroma industrial wastewater.

PDADMAC's dual function—removing both turbidity and color—makes it a preferred choice for industries requiring high transparency and aesthetically pleasing water quality.

Comparison of PolyDADMAC with Other Coagulants and Flocculants

PDADMAC is often compared to traditional coagulants such as alum (aluminum sulfate), ferric chloride, polyaluminum chloride (PAC), and non-ionic or anionic polymers like polyacrylamide (PAM). Understanding these differences helps water treatment professionals select the most effective solution for turbidity and color removal.

PDADMAC is often compared to traditional coagulants such as alum (aluminum sulfate), ferric chloride, polyaluminum chloride (PAC), and non-ionic or anionic polymers like polyacrylamide (PAM). Understanding these differences helps water treatment professionals select the most effective solution for turbidity and color removal.

Alum and Iron Salts: These are inorganic coagulants widely used for particle destabilization. While effective at removing turbidity, they typically require high dosages, generate large amounts of sludge, and may not be effective at removing color.

Polyaluminum Chloride (PAC): Compared to alum, PAC offers faster flocculation, lower dosage requirements, and better performance. However, its decolorization effect is often limited, and it has a narrower optimal pH range for best performance.

PAM (Polyacrylamide): Anionic or non-ionic PAM polymers are primarily used as flocculants for suspended solids but are less effective at removing dissolved color-causing compounds.

Poly(diallyldimethylammonium chloride) (PDADMAC): Unlike the above substances, PDADMAC combines a high cationic charge density with strong bridging effects, resulting in exceptional efficiency in both turbidity removal and color reduction. Furthermore, it generates less sludge and is effective over a wider pH range, providing operational flexibility and cost savings.

By integrating PDADMAC into their treatment processes, various industries can achieve clearer water while reducing chemical consumption and sludge disposal costs.

Typical Applications of PolyDADMAC

PDADMAC Dosage and Application Methods

The effectiveness of PDADMAC depends on the correct dosage and application method. Key considerations include:

- Dosage: Typical dosages for municipal wastewater treatment are 1–10 mg/L, and for industrial wastewater treatment, 5–50 mg/L. The specific dosage depends on turbidity, color, and water chemistry. Bench-scale testing is recommended to determine the optimal dosage.

- Application: PDADMAC can be added to the influent as a pre-diluted solution or directly to the flocculation tank.

- Mixing: Gentle, rapid mixing should be performed first to ensure even distribution, followed by slow mixing to promote floc formation.

- Contact Time: Flocs typically form within 10-20 minutes, depending on the water characteristics and polymer properties.

Optimizing these parameters is crucial for maximizing turbidity and color removal while minimizing chemical consumption.

Factors Affecting PolyDADMAC Performance

Several factors can influence the performance of PDADMAC in water treatment:

- Water pH: PDADMAC is effective over a wide pH range (4–10), but extremely acidic or alkaline conditions may reduce its efficiency.

- Temperature: Higher temperatures can accelerate floc formation, while very cold water may require longer mixing times.

- Suspended Solids Concentration: High turbidity levels may require higher polymer dosages.

- Organic Matter Content and Color: Water rich in humic substances or dyes may require pretreatment or combination with inorganic coagulants.

- Mixing Intensity: Excessive or insufficient mixing can disrupt formed flocs, reducing turbidity removal efficiency.

By monitoring these parameters and adjusting the dosage accordingly, water treatment operators can achieve consistent treatment results.

Advantages of Using PDADMAC

PDADMAC offers several advantages compared to traditional coagulants and flocculants, making it a preferred choice for water and wastewater treatment:

- High Efficiency: PDADMAC quickly removes turbidity and reduces color even at low dosages, resulting in cost savings.

- Versatile: Effective across a wide range of pH values, suitable for both municipal and industrial applications.

- Reduced Sludge Volume: Generates less sludge compared to inorganic coagulants, lowering disposal costs and environmental impact.

- Enhanced Sludge Dewatering: Improves sludge compressibility, simplifying treatment and drying processes.

- Compatibility: Can be used in combination with other coagulants (such as PAC or alum) to optimize complex wastewater treatment schemes.

- Water Reuse: By improving clarity and reducing color, water treated with PDADMAC can often be reused in industrial processes or safely discharged, supporting sustainability goals.

Storage and Safety of PolyDADMAC

While PDADMAC is generally safe to handle, following proper guidelines ensures its long-term stability and operational safety:

Storage: Store PDADMAC in a cool, dry place, away from direct sunlight and freezing temperatures. Liquid formulations should be stored in corrosion-resistant containers.

Shelf Life: The shelf life of liquid PDADMAC is typically 12-24 months; powdered PDADMAC has a longer shelf life if kept dry.

Handling: Wear gloves and eye protection when handling concentrated solutions to prevent skin or eye irritation.

Disposal: Dispose of unused polymer and sludge generated during processing according to local environmental regulations.

Proper handling and storage methods maintain the effectiveness of the polymer and ensure safe use for operators.

How to Choose a Reliable PDADMAC Supplier

For industries that rely on polydiallyldimethylammonium chloride (PDADMAC) for turbidity and color removal, choosing a reliable supplier is crucial. Key factors to consider include:

Manufacturing Experience: Suppliers with decades of experience can provide consistent quality and technical support.

Customizable Products: Offering different molecular weights, charge densities, and packaging to suit specific applications.

Technical Support: Assistance with dosage optimization, jar testing, and application guidance.

Supply Stability: Ensuring a consistent supply to avoid process interruptions.

Certifications and Compliance: ISO, REACH, or local regulatory approvals confirm product quality and safety standards.

Partnering with a trustworthy PolyDADMAC Supplier ensures operational efficiency, cost-effectiveness, and compliance.

PDADMAC is a highly effective cationic polymer that plays a crucial role in removing turbidity and reducing color in various water and wastewater treatment applications. Its high efficiency, versatility, and compatibility with other coagulants make it an ideal choice for municipal and industrial water treatment. For industries seeking clear, colorless water and optimized sludge management, PDADMAC offers operational and economic benefits. Choosing a reliable supplier with technical expertise ensures consistent performance, regulatory compliance, and long-term sustainability.

Post time: Feb-03-2026