In Industrial Wastewater Treatment, there will be many suspended small particles in the wastewater. To remove these particles and make the water clear and reused, it is necessary to use Water Chemical Additives - Flocculants (PAM) to make these suspended particles Impurities condense into bulky molecules and settle down.

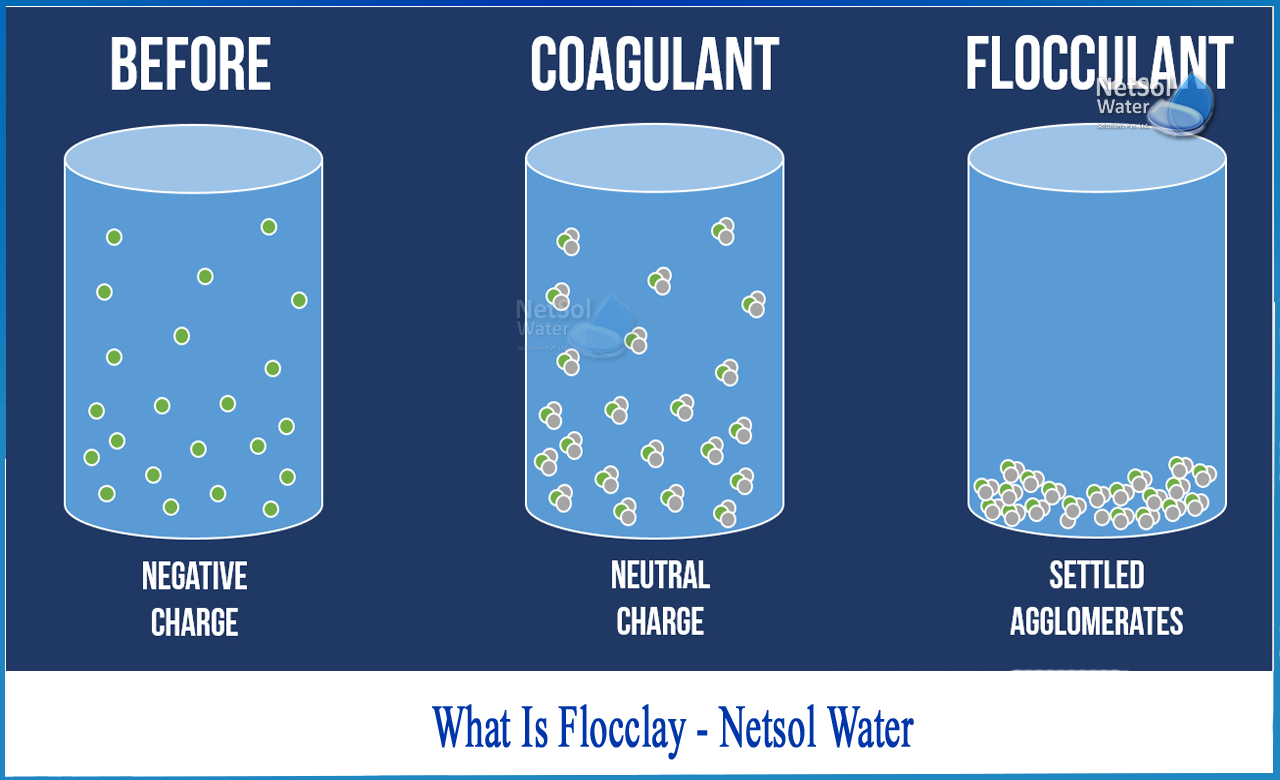

The colloid particles in the water are small, and the surface is hydrated and charged to make them stable. After the flocculant is added to the water, it is hydrolyzed into a charged colloid and its surrounding ions to form micelles with an electric double layer structure.

The method of rapid stirring after dosing is adopted to promote the chance and number of collisions between the colloidal impurity particles in the water and the micelles formed by the hydrolysis of the flocculant. The impurity particles in the water first lose their stability under the action of the flocculant, then coagulate with each other into larger particles, and then settle down or float up in the separation facility.

The product GT of the velocity gradient G generated by stirring and the stirring time T can indirectly represent the total number of particle collisions in the entire reaction time, and the coagulation reaction effect can be controlled by changing the GT value. Generally, the GT value is controlled between 104 and 105. Considering the influence of the impurity particle concentration on the collision, the GTC value can be used as a control parameter to characterize the coagulation effect, where C represents the mass concentration of impurity particles in the sewage, and it is recommended that the GTC value be between 100 or so.

The process of prompting the flocculant to diffuse rapidly into the water and mix evenly with all the wastewater is called mixing. The impurity particles in the water interact with the flocculant, and through mechanisms such as compression of the electric double layer and electrical neutralization, the stability is lost or reduced, and the process of forming micro flocs is called coagulation. The process of agglomeration and formation of micro flocs growing into large flocs through mechanisms such as adsorption bridging and sediment net capture under the agitation of bridging substances and water flow is called flocculation. Mixing, coagulation and flocculation are collectively called coagulation. The mixing process is generally completed in the mixing tank, and coagulation and flocculation are carried out in the reaction tank.

About the use of Polyacrylamide and its flocculation, you can contact the Water Chemical Manufacture to learn more

Post time: Dec-02-2022