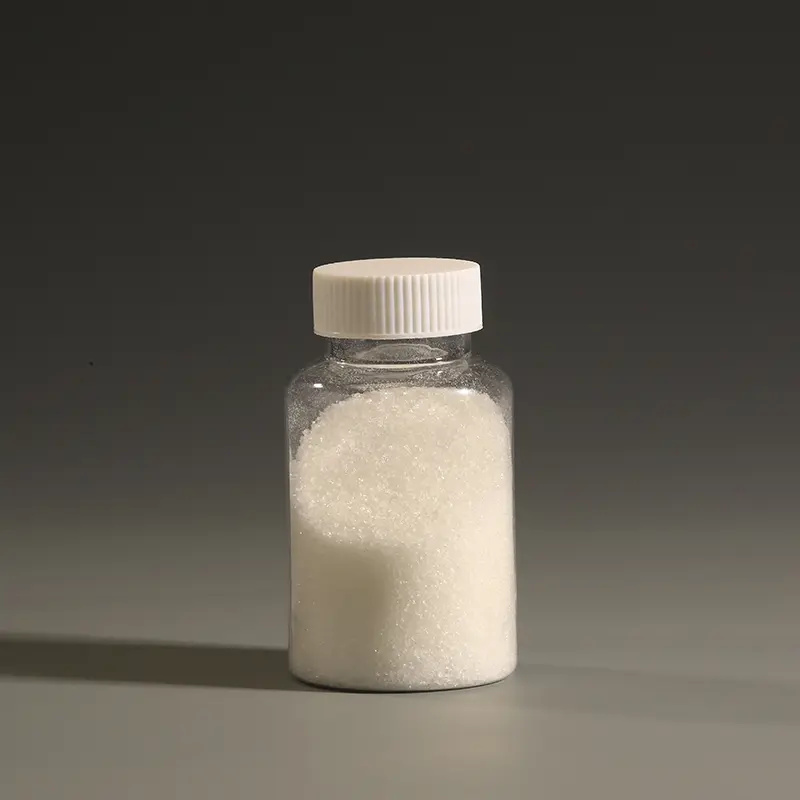

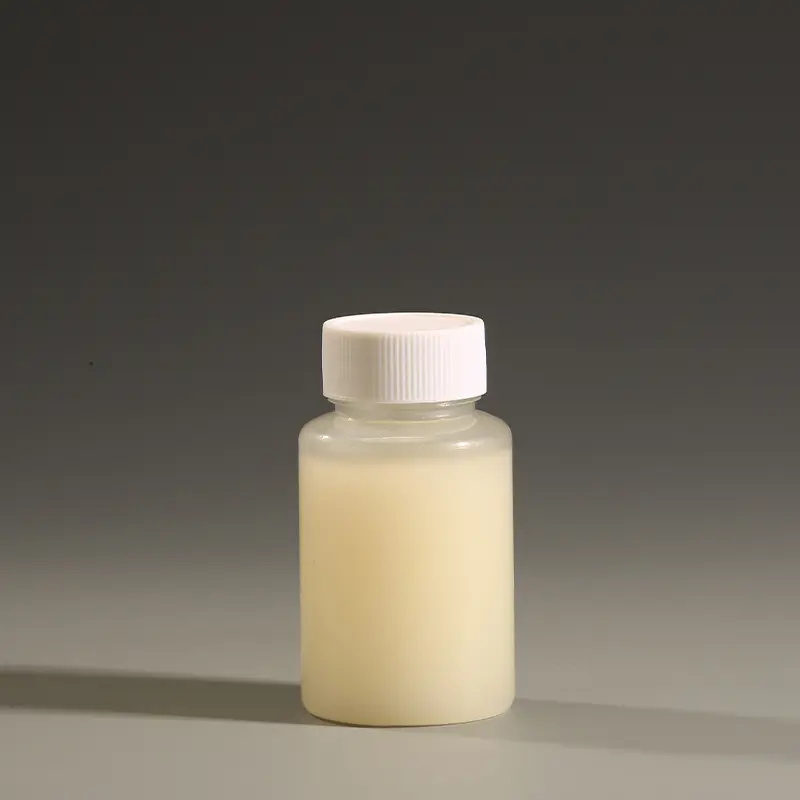

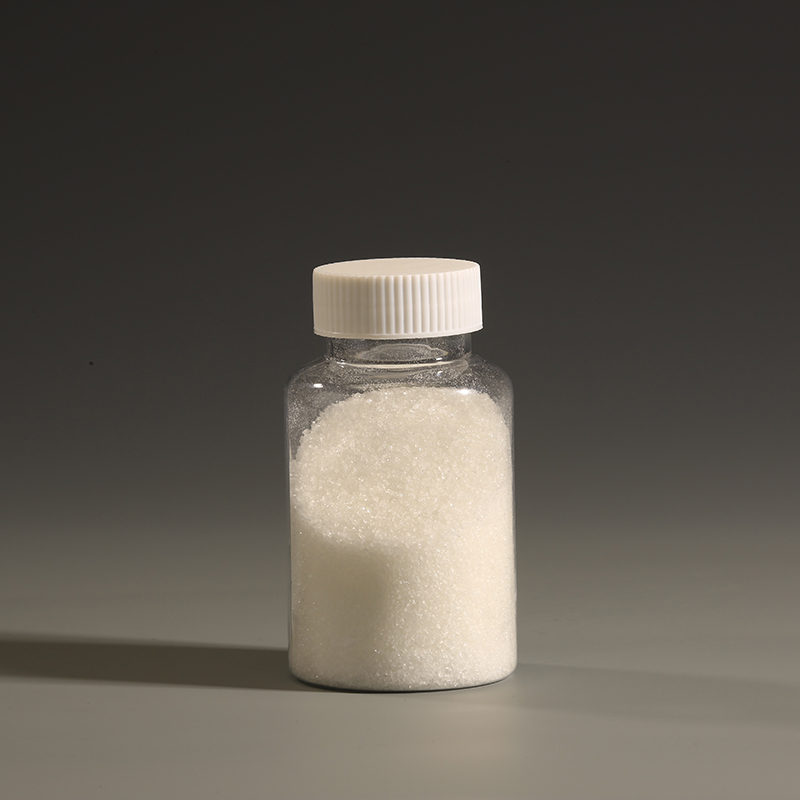

Cationic Polyacrylamide — (CPAM)

Introduction

Cationic polyacrylamide is a polymer (Also known as cationic polyelectrolyte). Because it has a variety of active groups, it can form adsorption with a variety of substances, and has functions such as turbidity removal, decolorization, adsorption, and adhesion.

As a flocculant, it is mainly used in solid-liquid separation processes, including sedimentation, clarification, sludge dehydration and other processes. It is often used for wastewater treatment in industrial wastewater, urban sewage, food processing, etc. Through its powerful coagulation effect, impurities are condensed into large flocs and thus separated from the suspension.

Storage and Precautions

1. Non-toxic, easily soluble in water and easily moisture absorption to caking.

2. Splashes on hand and skin should be washed off with water immediately.

3. Proper storage temperature : 5℃~40℃ ,should be stored in original packaging in cool and dry place .

4. Preparation solution of liquid polyacrylamide is not suitable for long storage. Its flocculating effect would decrease after 24 hours.

5. Low-hardness water with neutral PH range 6-9 is suggested to dissolve polyacrylamide. Using underground water and recycled water which also has high salt level would decrease the flocculating effect.

Applications

Cationic polyacrylamide (CPAM) is a type of water-soluble polymer that has a wide range of applications, primarily in water treatment, wastewater treatment, and various industrial processes. Here are some common applications of cationic polyacrylamide:

Water Treatment: CPAM is often used in water treatment plants to remove suspended solids, organic matter, and other contaminants from water. It helps in flocculation and sedimentation processes, allowing the particles to settle down and form larger aggregates that can be easily removed.

Wastewater Treatment: In wastewater treatment facilities, CPAM is utilized to enhance the efficiency of solid-liquid separation processes such as sedimentation, flotation, and filtration. It aids in the removal of pollutants and impurities from wastewater before it is discharged into the environment.

Papermaking: In the papermaking industry, it can be used as dry strength agent and retention aid. Greatly improve the quality of paper and save costs. It can directly generate electrostatic bridging with inorganic salt ions, fibers, organic polymers, etc., to enhance the physical strength of paper, reduce fiber loss, and accelerate water filtration. Can also be used for white water treatment. At the same time, it has obvious flocculation effect during the deinking process.

Mining and Mineral Processing: CPAM is used in mining and mineral processing operations for solid-liquid separation, dewatering of sludge, and tailings treatment. It helps in clarifying process water, recovering valuable minerals, and reducing the environmental impact of mining activities.

Oil and Gas Industry: In the oil and gas industry, CPAM is applied in drilling muds, fracturing fluids, and enhanced oil recovery processes. It helps to control fluid viscosity, improve fluid flow properties, and mitigate formation damage during drilling and production operations.

Soil Stabilization: CPAM can be used for soil stabilization and erosion control in construction projects, road building, and agriculture. It improves soil structure, reduces soil erosion, and enhances the stability of embankments and slopes.

Textile Industry: CPAM is employed in the textile industry for wastewater treatment, dyeing, and sizing processes. It aids in the removal of suspended solids, colorants, and impurities from textile wastewater, ensuring compliance with environmental regulations.

Municipal Solid Waste Management: CPAM can be utilized in municipal solid waste management systems for dewatering of sludge, landfill leachate treatment, and odor control.

How do I choose the right chemicals for my application?

You can tell us your application scenario, such as pool type, industrial wastewater characteristics, or current treatment process.

Or, please provide the brand or model of the product you are currently using. Our technical team will recommend the most suitable product for you.

You can also send us samples for laboratory analysis, and we will formulate equivalent or improved products according to your needs.

Do you provide OEM or private label services?

Yes, we support customization in labeling, packaging, formulation, etc.

Are your products certified?

Yes. Our products are certified by NSF, REACH, BPR, ISO9001, ISO14001 and ISO45001. We also have national invention patents and work with partner factories for SGS testing and carbon footprint assessment.

Can you help us develop new products?

Yes, our technical team can help develop new formulas or optimize existing products.

How long does it take for you to respond to inquiries?

Reply within 12 hours on normal working days, and contact via WhatsApp/WeChat for urgent items.

Can you provide complete export information?

Can provide a full set of information such as invoice, packing list, bill of lading, certificate of origin, MSDS, COA, etc.

What does after-sales service include?

Provide after-sales technical support, complaint handling, logistics tracking, reissue or compensation for quality problems, etc.

Do you provide product usage guidance?

Yes, including instructions for use, dosing guide, technical training materials, etc.