Sugar is a basic raw material for beverages, convenience foods, fast food, candies, pastries, and related industries. It is also often used as a seasoning in daily life. It has a wide range of uses and a huge demand. Sugar usually comes from sugar beets and sucrose. Sugar beets account for 20% of sugar production, while sugarcane makes up 80%. The top five sugarcane sugar producers in the world are Brazil, India, China, Thailand, and Pakistan. The top five sugar beet producers in the world are France, the United States, Germany, Russia, and Turkey.

When making sugar, a large amount of wastewater and sugar juice is produced. These wastewater and sugar juice need to be treated during processing or discharge to meet the standards. Clarification is the most crucial step among them.

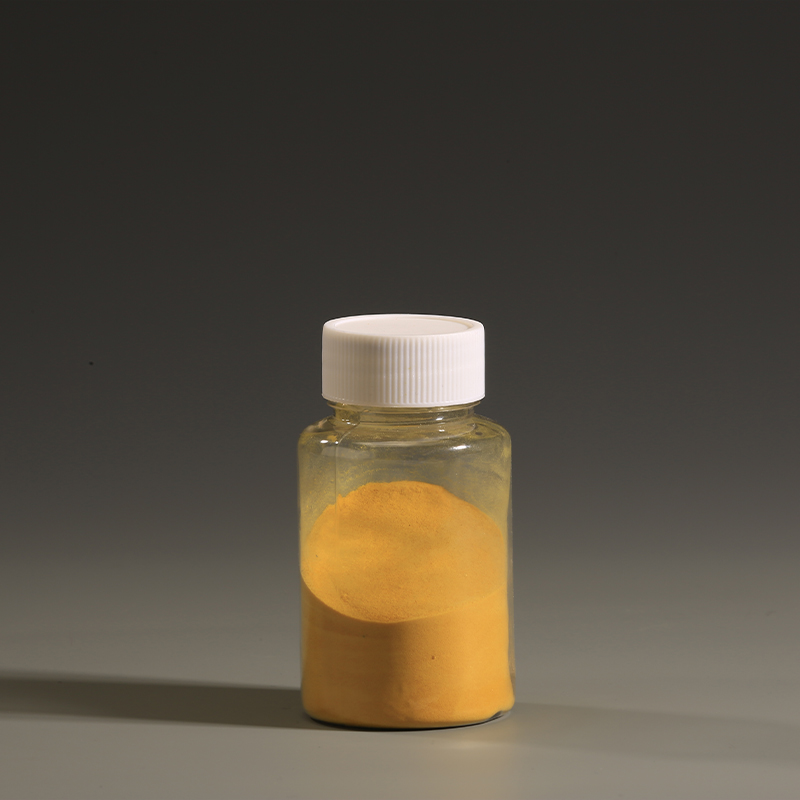

Over the past decade, Polyaluminium Chloride has been widely used in sugar factories around the world due to its high efficiency and stability. Become one of the most popular coagulants. From the purification of sugar juice to the treatment of COD in wastewater, PAC offers the most suitable solution for the sugar industry.

The Application of PAC in the Sugar Industry

Polyaluminium chloride can effectively break down and aggregate suspended particles, colloids and dissolved organic matter. It is an inorganic polymer clarifying agent with a high degree of polymerization and high charge density. It is often used in the sugar industry for:

- Clarification of sugarcane juice or beet juice.

- Remove color and reduce turbidity.

- Enhance sedimentation and filtration performance.

- Wastewater treatment before being discharged or reused.

Unlike traditional coagulants such as aluminium sulfate or lime, PAC functions effectively over a wider pH range, generates less sludge and has a faster coagulation rate.

Polyaluminium Chloride is Used for Clarifying Sugar Juice

Unprocessed sugar juice contains various impurities: suspended solids, plant fibers, colloids, proteins, polysaccharides, pigments, soil, and inorganic particles, etc. These impurities will affect the purity of the sugar juice, the crystallization efficiency, the quality of the finished sugar, etc. PAC can remove suspended and dissolved impurities; this effect is called clarification.

The Mechanism of Action of Polyaluminium Chloride in Juice Clarification

· The positive charge of polyaluminium chloride neutralizes the negative charge on colloids and fine particles, making them unstable.

· Capture proteins, sand particles, pigment compounds and other substances in the liquid, causing them to form larger flocs that rapidly settle in the clarifier.

· Moreover, PAC can also adsorb compounds that cause liquid coloring, making the color of the sugar syrup lighter and thus making the color of the finished product more transparent.

Advantages of PAC in Juice Purification

* Better reduction effect in juice clarity and color

* Faster settling speed and shorter residence time

* Reduced the turbidity of clarified juice

* Reduced scaling in evaporators and heaters

* Higher sugar yield due to improved crystallization ability

* Lower chemical consumption compared to traditional coagulants

* Reduced sludge volume and simplified sludge filtration

Overall, PAC improves operational efficiency while enhancing the quality of the final sugar product.

The Recommended Dosage of PAC for Juice Clarification

The common dosage depends on the quality of the juice, the type of sugarcane or beet, and the required purity. Common dosage ranges include:

The dosage of PAC in raw sugarcane juice is 20-50 mg/L

When used in conjunction with auxiliary flocculants, the concentration of PAC is 10-30 mg/L.

For high-impurity or rainy season fruit juices, the dosage of PAC is 40-80 mg/L.

Dose optimization is best carried out through laboratory beaker tests.

Determine the optimal dosage based on the different turbidities of the sugar juice.

Polyaluminium Chloride: Used for the Treatment of Sugar Industry Wastewater

If sugar industry wastewater is discharged without treatment, it will cause pollution problems to aquatic and terrestrial ecosystems. In addition, if the sugar industry wastewater is not completely treated, it will produce an unpleasant smell when released into the environment. The main sources of wastewater from sugar factories include the juicing and cleaning processes, boiler blowdown, filtration and clarification processes, equipment cleaning operations, as well as condensate water and cooling water, etc.

The Characteristics of Sugar Industry Wastewater

This type of wastewater usually contains organic matter (COD and BOD), suspended solids, pigments, oils and other substances. It has a brown color, a low pH value, an odor problem, a high total solid content, and a relatively high proportion of dissolved organic and inorganic substances.

The Working Principle of PAC in Wastewater Treatment

PAC achieves effective wastewater treatment in the following ways:

· Coagulation and sedimentation

It can disrupt the stability of suspended solids and organic colloids, thereby promoting the rapid formation of flocs.

· The chemical oxygen demand and biological oxygen demand have decreased

PAC can remove dissolved organic compounds that cause a large COD/BOD load.

· Decolorization

PAC can adsorb chromogenic compounds and pigments in wastewater.

· The volume of sludge decreases

The sludge produced by PAC has a higher density, is more compact, and is easier to handle and dewater.

The Benefits of PAC in Wastewater Management

- Depending on the factory conditions, the COD removal rate can reach 60% to 85%.

- Turbidity and total suspended solids (TSS) have been significantly improved

- Increase the sedimentation rate in the clarifier

- Compared with alum or ferrous salts, the sludge production is lower

- It is stable in performance within a wide pH range (5-9)

- The demand for pH adjustment chemicals has been reduced

- Improvement of the performance of the biological treatment system

- These advantages make PAC the preferred choice for sugar factories that pursue compliance and cost-effectiveness.

Recommended PAC Dosage for Wastewater Treatment

PAC dosage varies depending on wastewater characteristics:

Generally, the concentration is 30–150 mg/L. For high-COD wastewater, the concentration is 100–200 mg/L.

When used with flocculants (such as PAM), the concentration is 20–50 mg/L.

Correct dosage ensures effective clarification without overdose or unnecessary costs.

PAC Addition Points in Water Treatment

Pretreatment Stage: This is the main point for PAC addition, where it effectively destabilizes colloidal particles and reduces turbidity.

Before Flocculation and Sedimentation: Combining PAC with a flocculant such as PAM at this stage achieves optimal coagulation and sedimentation performance, improving overall water clarity and treatment efficiency.

Synergistic Use of PAC with other Flocculants

Often used in combination with PAM (Polyacrylamide) to improve floc strength.

For high color intensity, a decolorizing agent can be added.

Optimal effect at pH 6.5–7.5; lime can be used to adjust the pH.

Polyaluminum chloride (PAC) has become an indispensable chemical additive in the modern sugar industry due to its high efficiency, stability, and adaptability in sugar juice clarification and wastewater treatment. Compared with traditional coagulants, PAC offers several advantages: a wider pH range, faster settling speed, less sludge production, and higher operational efficiency and sugar yield. By precisely controlling the dosage of PAC and combining it with auxiliary flocculants such as polyacrylamide (PAM), sugar plants can achieve optimal clarification results and cost-effectiveness.

More information about the sugar industry can be found in "Chemical Solutions for the Sugar Industry". Hopefully, this will be helpful to you.

Post time: Dec-02-2025