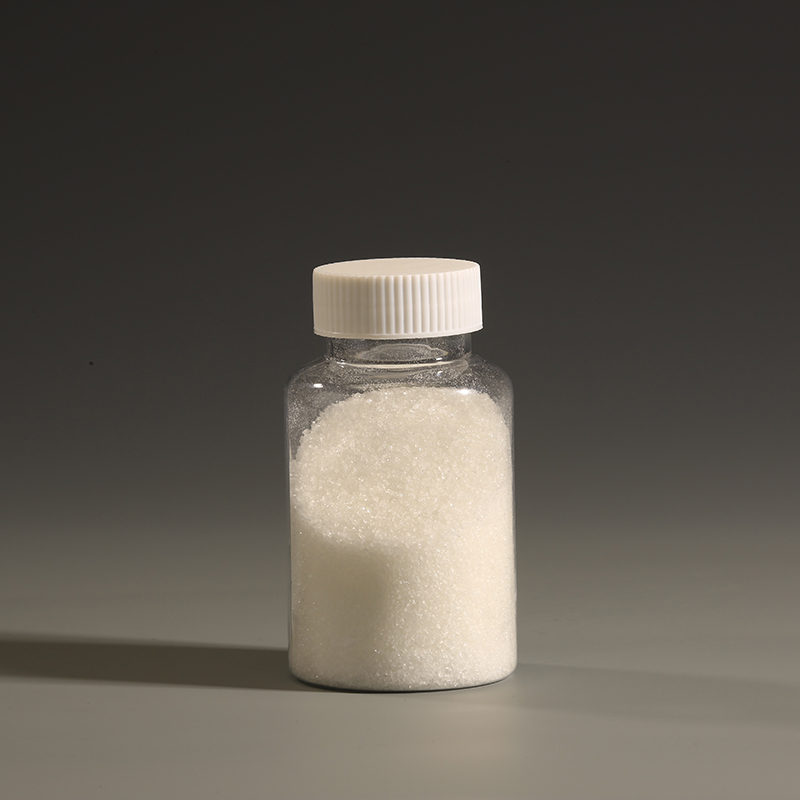

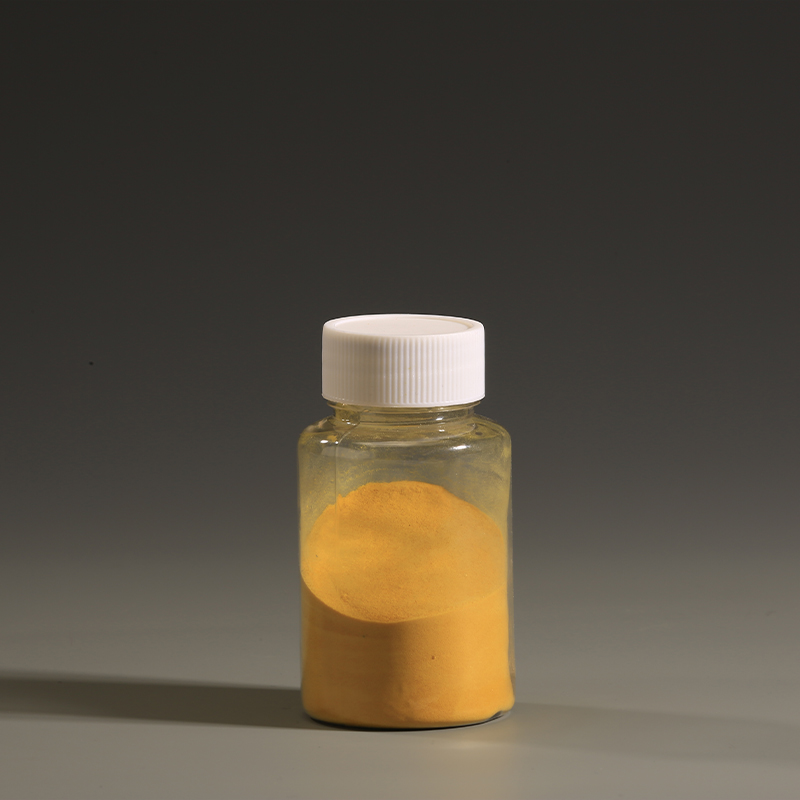

Flocculant – Polyacrylamide (PAM)

How do I choose the right chemicals for my application?

You can tell us your application scenario, such as pool type, industrial wastewater characteristics, or current treatment process.

Or, please provide the brand or model of the product you are currently using. Our technical team will recommend the most suitable product for you.

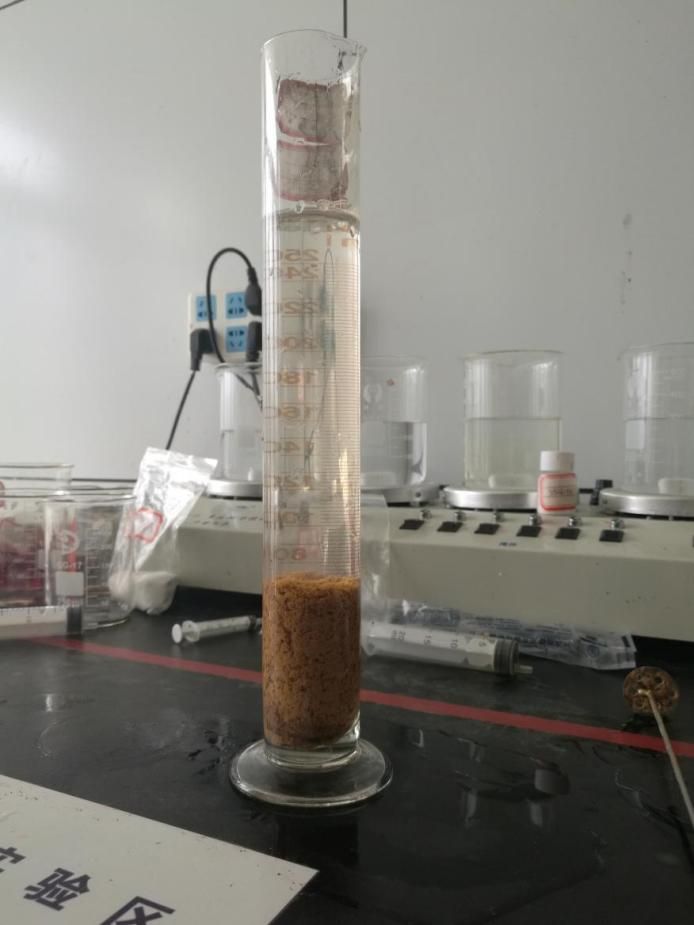

You can also send us samples for laboratory analysis, and we will formulate equivalent or improved products according to your needs.

Do you provide OEM or private label services?

Yes, we support customization in labeling, packaging, formulation, etc.

Are your products certified?

Yes. Our products are certified by NSF, REACH, BPR, ISO9001, ISO14001 and ISO45001. We also have national invention patents and work with partner factories for SGS testing and carbon footprint assessment.

Can you help us develop new products?

Yes, our technical team can help develop new formulas or optimize existing products.

How long does it take for you to respond to inquiries?

Reply within 12 hours on normal working days, and contact via WhatsApp/WeChat for urgent items.

Can you provide complete export information?

Can provide a full set of information such as invoice, packing list, bill of lading, certificate of origin, MSDS, COA, etc.

What does after-sales service include?

Provide after-sales technical support, complaint handling, logistics tracking, reissue or compensation for quality problems, etc.

Do you provide product usage guidance?

Yes, including instructions for use, dosing guide, technical training materials, etc.